CALMAST® MF550 from ADC PLASTIC is produced with the following mixing formula:

Primary Plastic Resins (PP) + Filler Material (CaCo3 Powder) + Processing aid additives (Dispersion aid, lubricant, ..)

CALMAST® MF550 is a perfect choice to help plastic product manufacturers optimize costs and improve mechanical and physical properties such as heat resistance, surface improvement, increased tear strength, and tensile strength of the finished product. Especially increase the stability in the processing of the final product.

CALMAST® MF550 is recommended for products with a thickness of 13 microns or more and can be processed at temperatures ranging from 200°C to 300°C. The suggested dosage is between 5% and 60%, tailored to your specific needs.

Some common applications of MF550 (PP Calcium Carbonate Filler Masterbatch) in Spinning yarn and weaving bags with woven bags a load capacity of 100kg or more (PP WOVEN BAG) include Food packaging, cereals, rice packaging, chemical fertilizer packaging, …)

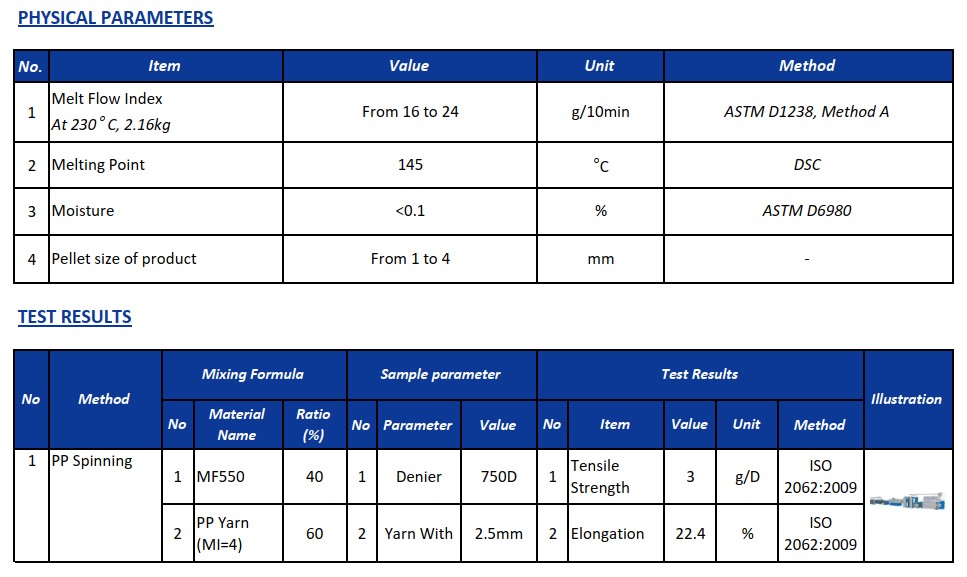

TECHNICAL DATA SHEET OF CALMAST® MF550

ABOUT ADC PLASTIC

ADC PLASTIC is the first manufacturer in Vietnam to pioneer the field of Plastic Masterbatch with nearly 20 years of experience in producing and exporting CaCo3 Filler and White Masterbatch. Currently, ADC PLASTIC owns a factory of 15,000 m2 with a total capacity of more than 460,000 Tons/year. We are a strategic and reliable partner of thousands of enterprises in Vietnam as well as around the world in Europe. Asia, Middle East, America …

ADC PLASTIC provides customized CaCo3 Filler Masterbatch products that meet all customer requirements for QUALITY – QUANTITY – DELIVERY TIME to help plastic enterprises improving performance, optimizing prodution costs.